Precision Sorting: The Indispensable Role of a Paddy Separator

In the complex journey of rice milling, each machine plays a specific and crucial role. After paddy is hulled (the husk removed), the output is not pure brown rice. It’s a mixture of:

- Brown Rice: Paddy that has been successfully de-husked.

- Unhusked Paddy: Grains that passed through the husker without having their husk removed.

- Broken Rice: Grains that broke during the hulling process.

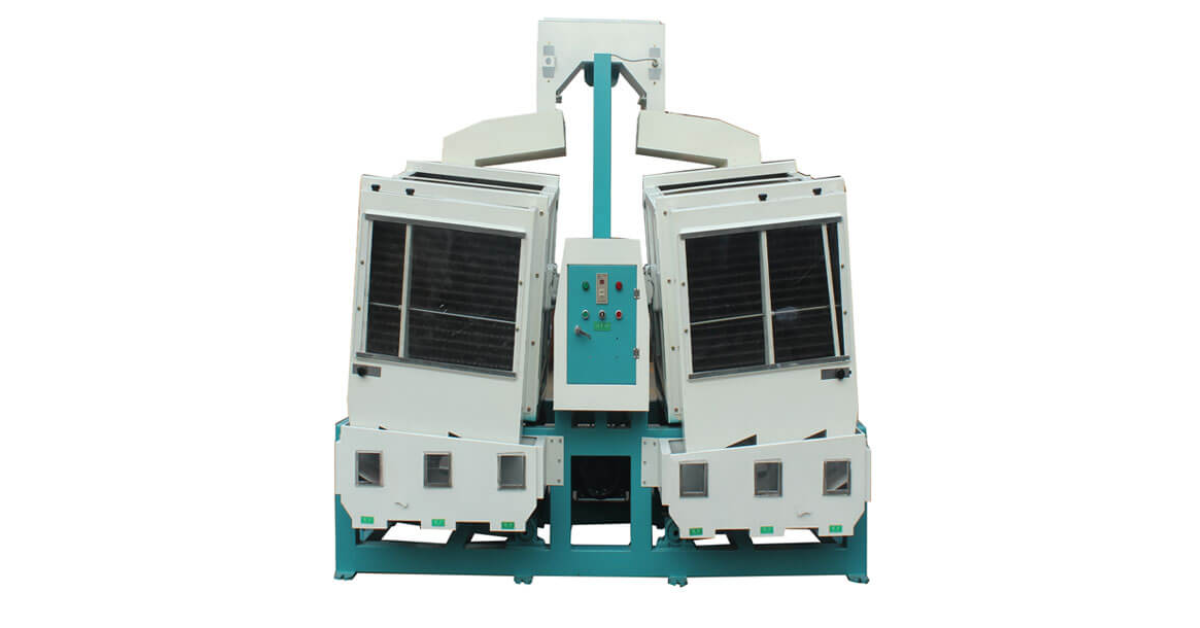

This is precisely where the Paddy Separator steps in – a vital piece of equipment designed to efficiently separate the unhusked paddy from the brown rice, ensuring optimal efficiency and quality in subsequent milling stages. At Ricetec Machinery, we provide advanced paddy separators engineered for high precision and reliable performance.

Why is a Paddy Separator Essential?

The paddy separator’s role is critical for several reasons:

- Optimizing Huller Efficiency: Sending unhusked paddy back to the husker for re-processing ensures that the husker operates at its peak efficiency, only dealing with grains that need de-hulling. Without a separator, brown rice would be repeatedly fed through the husker, causing unnecessary wear on rubber rollers and potentially increasing breakage.

- Preventing Damage to Whiteners/Polishers: Brown rice is sent to the whitener, while unhusked paddy, if not separated, could damage the abrasive components of the whitener and polisher, leading to increased maintenance costs and reduced machine lifespan.

- Ensuring Consistent Product Quality: Effective separation guarantees that only clean brown rice proceeds to the whitening stage, leading to a more uniform and higher-quality final white rice product.

- Maximizing Yield: By re-processing unhusked grains, the overall yield of brown rice from the paddy is maximized, directly impacting profitability.

- Reducing Energy Consumption: By efficiently recycling unhusked paddy, the energy spent on processing already-hulled grains is minimized.

How a Paddy Separator Works: Leveraging Physical Differences

Paddy separators operate on the principle of leveraging the subtle differences in physical properties between unhusked paddy and brown rice. While they might look similar, these two forms of rice differ in:

- Specific Gravity (Density): Brown rice is generally denser than unhusked paddy (due to the presence of the lightweight husk).

- Coefficient of Friction/Surface Roughness: Paddy has a rougher, stickier surface (due to the husk), while brown rice is smoother.

- Size and Shape: Though minimal, there can be slight differences in overall dimensions and how they behave under specific conditions.

The most common types of paddy separators utilize an inclined, reciprocating (back-and-forth) motion of trays or screens to achieve this separation:

- Feeding: The mixture of brown rice and unhusked paddy (and sometimes broken rice) from the husker is fed evenly onto the top of the separator’s inclined trays.

- Oscillating Movement: The trays oscillate with a specific frequency and amplitude. This constant motion causes the grains to stratify and move.

- Stratification and Separation:

- Due to its higher density and smoother surface, the brown rice tends to “sink” to the lower layer of the tray surface and moves downwards along the inclination, discharging from one outlet.

- The lighter, rougher paddy tends to “float” on the upper layer and, aided by the friction with the tray surface and the specific oscillating motion, moves upwards along the inclination, discharging from a separate outlet.

- Often, a third, middle outlet might collect a mixture that is then re-circulated for further separation, or a dedicated broken rice outlet might be present.

- Recirculation: The separated unhusked paddy is automatically conveyed back to the paddy husker for another pass, while the clean brown rice proceeds to the whitening section.

Types of Paddy Separators

While the gravity-based, oscillating tray principle is dominant, variations exist:

- Gravity Paddy Separators: The most common type, relying on density and friction differences.

- Inclined Tray Paddy Separators: Specifically refers to the design with angled trays.

- Vibrating Tray Paddy Separators: Emphasizes the vibratory motion as the primary separation mechanism.

- Single Body vs. Double Body: Refers to the number of parallel separation units within the machine. Double body separators offer higher capacity.

- Butterfly Paddy Separators: A popular design often featuring a unique arrangement of trays that resembles a butterfly.

Key Features of an Efficient Paddy Separator

When considering a paddy separator for your rice mill, look for the following features:

- High Separation Efficiency: The machine should achieve near-perfect separation (e.g., less than 10% paddy in the brown rice stream and minimal brown rice in the paddy stream).

- Adjustable Parameters: The ability to adjust the inclination, oscillation speed, and amplitude to optimize separation for different varieties of paddy.

- Durable Construction: Built with robust materials (e.g., high-quality steel, sometimes stainless steel for contact parts) to withstand continuous operation and minimize wear and tear.

- Low Noise and Vibration: Important for a better working environment and longevity of the machine.

- Low Power Consumption: Contributes to lower operational costs.

- Easy Maintenance: Simple access for cleaning and routine checks.

- Automatic Control: Integration with the mill’s central control system for seamless, automated operation.

Ricetec Machinery: Precision Paddy Separators for Optimal Milling

At Ricetec Machinery, our paddy separators are designed with precision engineering and a deep understanding of rice milling dynamics. We offer a range of models, including both single and double body butterfly separators, to cater to various mill capacities. Our machines are characterized by:

- Superior Separation Accuracy: Ensuring maximum recovery of brown rice and efficient recycling of unhusked paddy.

- Robust and Durable Build: Constructed with high-quality materials for extended operational life.

- Energy Efficiency: Designed to minimize power consumption.

- User-Friendly Operation: Easy to adjust and maintain for optimal performance.

- Seamless Integration: Designed to integrate perfectly into automatic rice mill lines.

A high-performing paddy separator is not just a machine; it’s a critical component that ensures the efficiency of your entire rice milling plant, protects your valuable machinery, and ultimately contributes to the consistent quality and profitability of your final rice product. Contact Ricetec Machinery to learn more about how our paddy separators can enhance your milling operations.